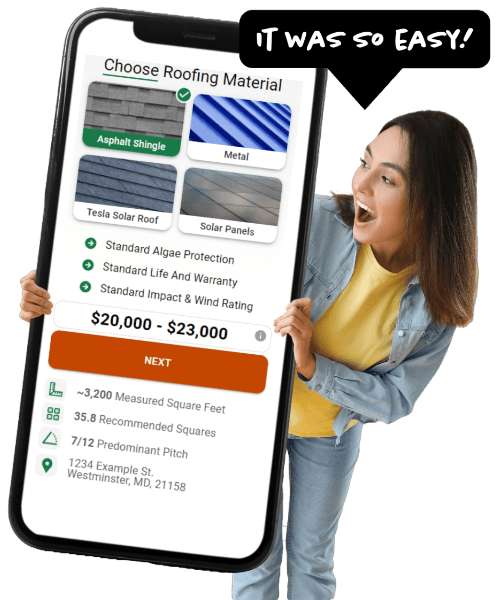

Metal Roof Cost Calculator

Instant Roofer harnesses cutting-edge AI technology to deliver precise estimates tailored to your home with our metal roof cost calculator. The current average cost for a metal roof is . We provide free, accurate, and instant metal roof estimates in seconds—then help you connect with the perfect contractor in your area. Say goodbye to guesswork and endless phone calls—get your free instant metal roof estimate today!

- Quick, Easy, Reliable – Know your roof replacement costs in seconds

- Instant Roof Measurements – Powered by advanced AI technology

- Accurate Cost Estimates – Tailored to your exact roof size and material choice

- Compare Contractors Easily – See up to 3 top-rated local pros

- No Signup Required – Get your estimates hassle-free

- Trusted by Homeowners – Backed by real reviews and transparent pricing

Measure

Roofs measured by our roofing calculator in the United States

Estimate

Average roof replacement cost for a metal roof in the USA

Connect

Highly rated roofers nationwide

How much does a metal roof cost?

A metal roof can cost in the ballpark of $8,000 to $80,000 depending on your location and available options, with the overall average nationwide being as of . If you want to go for a metal roof during your roof replacement, be ready for the fact that it is one of the most expensive options available. There are amazing benefits for choosing metal as your roofing material, and those benefits are the reason the cost can definitely go up! Factors include the numerous options available for metal roofing materials, as well as factors such as home size, roof slope, regional labor prices, and other considerations outlined below.

Factors that can impact your roof replacement costs include:

1. Choice of Metal

The choice of your metal can impact the curb appeal of your home as well as the next time you’ll need to replace it. Some metals last longer, are more weather-impact resistant, or offer more custom options. The chart below shows that the cheapest metal roofing option would be galvanized steel and the most expensive is copper.

2. Roof Complexity

Depending on the style of your roof, metal roofing costs can go up because of specialized cutting experience and the extra material that may be needed on more complex roof structures. Things including its pitch, slope, and architectural features can influence the overall cost.

3. Installation Cost

While considering the choice between metal and asphalt, you have probably asked yourself this question, “Are metal roofs cheaper than asphalt roofs?” Metal roofing does require a unique technique and contractors should have more experience than installing just asphalt roofs, which is why the cost of labor when installing a metal roof can be higher than that of an asphalt roof.

4. Metal Thickness & Coatings

Your metal roof can come in a variety of different thicknesses (the thicker, the more expensive) and different finishes. Higher-quality coatings and finishes can affect the overall costs. They can be coated with a variety of options like paint, stone granules, and even ceramic.

5. Custom Features

If your roof features unique things like insulation, multiple chimneys, ventilation systems, or skylights, these can contribute to the overall cost as laborers have to cut and fit your new metal roof to fit these smaller and more complex places. Depending on the type of metal your choose, there are also a ton of metal roof colors you can choose from to customize the look of your home.

As a rough estimate according to data collected from roofing leads across the US, the cost of a metal roof can range from $5 to $15 per square foot of roofing material. Remember this is a general estimation and can be higher based on the factors above! Obtain several quotes from multiple roofing contractors in your area for a more accurate estimate tailored to your specific project. And if you’re considering a different material, hop over to our roof replacement cost calculator to see your best options!

The Fastest Metal Roof Cost Calculator

There are more than a few dozens of roofing contractors in your area who are ready and actively available to send you an estimate on your roof. But how do you find a roofer that is reliable and reputable? Instant Roofer has made it easy to get a reliable range as well as connect you with local roofers in your area just by entering your address. We compile, rate, and connect the best rated roofers in your area with you, so you don’t have to do the heavy lifting. Our metal roof cost calculator makes it easy to be in-the-know about current roofing costs so you can plan ahead.

Metal roofing requires a different level of experience and contractors that understand custom-built styling, meaning that metal roofers are more specialized and experienced which is why getting hold of one in your area might be more difficult than anticipated. Just because you can get pricing for a copper metal roof online somewhere, doesn’t mean there is a contractor or distributor in your area that supports installation of copper metal roofs. Instant Roofer can help!

If you are considering another material for your home, check out our other calculators below!

- Asphalt Shingle Roofing Cost Calculator

- Cedar Shake Roof Cost Calculator

- Tesla Solar Roof Calculator

- Solar Panel Cost Calculator

Metal Roof Material Types and Their Prices

The metal roof market is constantly changing. Many new products are coming to the market each year. We’re going to focus on the main metal material types and their costs. All of the pricing is based on a 2,000 square foot home with an average slope roof

| Material | Low Cost | High Cost |

|---|---|---|

| Galvalume Steel | $8,000 | $18,000 |

| Galvanized Steel | $9,000 | $34,000 |

| Aluminum | $13,000 | $42,000 |

| Stainless Steel | $14,000 | $40,000 |

| Tin (Terne) | $20,000 | $52,000 |

| Zinc | $29,000 | $42,000 |

| Copper | $40,000 | $80,000 |

Galvalume Steel

Galvalume Steel is a specialized type of steel used in metal roofing applications. It is produced by coating steel with a special aluminum-zinc alloy, which typically consists of 55% aluminum, 43.4% zinc, and 1.6% silicon. This unique composition provides Galvalume Steel with several advantageous properties that make it an excellent choice for metal roofing systems.

Galvalume Steel Advantages:

- Manufacturing process: Galvalume Steel begins with a hot dip coating procedure that consists of immersing steel sheets in a bath consisting of molten Zinc and aluminum before following with subsequent cool and annealing processes. This results in the coating and the metal substrate being so well bonded that it guarantees performance and durability.

- Protective coating: Use of aluminum-zinc alloy coating on the Galvalume Steel provides two layers for protection against corrosion. The aluminum portion acts as a barrier to oxidizing agents and moisture while the zinc offers galvanic protection cut protecting the steel underneath.

- Heat reflectivity: Galvalume Steel is known to have a high solar reflectance which translates to it being able to reflect a lot of the heat from the sun and thus reducing the amount of heat that goes into the building. This can be a great advantage during the hot summer months, as there is less need for air-conditioning reducing dependency on energy systems and lowering electricity costs.

- Aesthetic options: While Galvalume Steel has a distinct, natural appearance characterized by a subtle, spangled pattern, it can also be coated with various paint finishes to match the desired aesthetic. This offers homeowners and building owners the opportunity to customize the appearance of their metal roof to suit their preferences.

- Compatibility with other materials: Galvalume steel may be used with practically all construction materials such as wood, brick, and concrete. Care should be taken, however, to ensure that copper does not come into contact with it because this will cause the roof to suffer from galvanic corrosion.

- Installation: It is important to have a professional install the Galvalume steel roofing systems in order to give them the best chance of functioning well for a long time. Missed installation techniques such as use of fasteners, flashing and underlayment materials and instructions from the manufacturer can also lead to poor roof performance.

- Cost: Galvalume Steel is generally more affordable than other premium metal roofing materials, such as copper or zinc. However, its cost may be higher than traditional asphalt shingles or basic metal options, such as galvanized steel.

- Weight: It is the low weight of Galvalume Steel that is its most prominent feature. Galvalume Steel roofing has a much lesser weight as compared to traditional roofing materials like clay shingles, tiles, and slate. This lesser weight reduces the load on the supporting components of a structure and makes the whole system easier to assemble and install on site.

Galvanized Steel

Galvanized Steel roofing has been coated with a layer of zinc for corrosion protection. The zinc coating helps prevent rust from forming on the steel, extending its lifespan and making it a popular choice for various applications, including roofing and siding. Painting a galvanized steel roof can provide a wide range of color options, allowing homeowners and building owners to customize the look of their roofs to match their preferences or the architectural style of their properties.

Galvanized Steel Roofing Advantages:

- Corrosion Resistance: Since it is galvanized, steel is less prone to corrosion because the zinc coating extends the useful life of the steel.

- Durability: Galvanized steel is a strong and durable material that can withstand various weather conditions, including wind, hail, and heavy snowfall, making it suitable for different climates and regions.

- Cost-Effective: Galvanized steel roofing is generally more affordable than other premium metal roofing materials, such as copper or Galvalume Steel, making it an attractive option for budget-conscious homeowners and building owners.

- Low Maintenance: Compared to wood or asphalt shingles, galvanized steel roofing requires very little upkeep and maintenance. Usually, a combination of inspection and cleaning is enough to ensure that the roof remains in great condition.

- Versatility: Different profiles such as corrugated, standing seam, and ribbed panels are available for galvanized steel roofing, which makes it useful for a variety of architectural styles.

- Easy Installation: Galvanized steel roofing is relatively easy to install due to its lightweight nature and standardized profiles, which means time and labor costs can be saved during the construction work.

- Recyclability: Galvanized steel is a recyclable material, which can help reduce construction waste and contribute to more sustainable building practices.

- Paintable Surface: Galvanized steel roofing can be painted or coated with various finishes to achieve the desired aesthetic appearance and provide an additional layer of protection against the elements.

Aluminum

Aluminum roofing is especially lightweight and durable metal roofing structure suited for residential and commercial construction. It has a number of advantages including resistance to corrosion, energy efficiency as well as long life., making it a popular choice for homeowners and building owners seeking a low-maintenance and environmentally friendly roofing solution.

Aluminum roofing advantages:

- Corrosion resistance: Aluminum naturally forms a thin oxide layer on its surface, providing excellent protection against rust and corrosion. This characteristic makes aluminum roofing particularly suitable for coastal regions or areas with high humidity, where other metal roofing materials may corrode more rapidly.

- Lightweight: Because aluminum is lightweight, it can help relieve some of the stress on a structure’s supportive elements. Lightweight aluminum is also easy to ship and install. This could save both time and labor costs.

- Energy efficiency: Aluminum roofing has high solar reflectance which means a building will utilize less energy since a vast amount of heat from an aluminum rooftop surface is reflected away. This will allow for a cooler environment within the building hence less energy is consumed on air conditioning. This will also reduce the costs associated with utility bills.

- Longevity: Under proper maintenance aluminum roofs can last for 50 years or even more. This long-lasting strength comes with savings over a longer time since the need to change the roof as with other roofing materials will not be necessary.

- Aesthetic options: Among the most widely used materials for aluminum roofing are shingles, tiles or standing seam. Further, aluminum roofing can be painted with styles and colors to match with the design of the building.

- Environmentally friendly: Aluminum is a material that can be recycled thus cutting down on wastage of materials during construction. Furthermore, it can be used to lower energy consumption and cut the environmental impact of a building overall.

- Low maintenance: Aluminum roofing requires minimal maintenance compared to other roofing materials. Regular inspections and occasional cleaning are typically sufficient to keep the roof in good condition.

- Cost: It is recognized that the cost of an aluminum roof will differ owing to different factors such as the type, its thickness and the finish. It is however worth noting that while the cost of an aluminum roof may be higher when compared to other kinds of metal roof types such as the galvanized steel, the longevity and lesser servicing on the roof may compensate the high initial cost.

Stainless Steel

Stainless steel roofing falls within the category of quality roofing materials that are long lasting, robust and have the ability to withstand corrosion. Also, it is important for its ability to resist tough environmental conditions earning it a certain appeal for a variety of residential, commercial and industrial purposes.

Stainless steel roofing advantages:

- Corrosion resistance: As an alloy steel, 10.5% chromium is present on stainless steel and forms a thin layer of oxide that cannot be seen and which self-repairs on the surface of the steel. This oxide layer offers great protection from rust and corrosion therefore stainless steel roofing can be recommended for different places including coastal areas and regions where there is high humidity or corrosive environments.

- Durability and strength: A distinguishing characteristic of stainless steel is the ability to endure severe weather elements like wind, hail, and snow without weakening or degrading over time. When properly installed and maintained, stainless steel with a high tensile strength and excellent fatigue resistance can be an effective roofing option, often lasting decades.

- Aesthetic options: Some of the most common types of stainless steel roofing include standing seam, shingle, tile, and corrugated paneling. Depending on how the material is meant to look in the end, it can have a polished or matte finish. Sometimes it is also possible to apply different colored layers to stainless steel in order to give it a unique appearance.

- Low maintenance: Unlike other forms of roofing that can easily wear, stains and rust is not a concern for a stainless steel roof. In most cases, periodic checks and cleaning are adequate to ensure the roof remains intact.

- Environmental considerations: Aged stainless steel roof panels or off-cuts may be readily recycled, thereby reducing construction material waste. Further, a stainless steel roof has little to no upkeep, meaning the need for replacements and the resources involved in manufacturing them are greatly lowered, reducing its environmental effect.

- Fire resistance: Steel is not combustible and does not aid the spread of fires. This is beneficial for a building’s overall fire ratings and is useful in regard to protection standards and other regulations.

- Cost: Stainless-steel roofing is generally more expensive than other metal covers like aluminum and galvanized steel due to the thicker material. However because of its longevity and corrosion resistance, it may be more economical in the long run.

- Reflectivity: A stainless steel roof panel has the advantage of being reflective surface materials in which less heat is absorbed into the building as sunlight is deflected away. This feature can help improve the comfort of the indoor spaces during hot summer months and cooling system energy usage. Reflectivity can also be a consideration in urban areas, where it can help mitigate the urban heat island effect by reducing the overall temperature in densely built environments.

Tin (Terne)

Tin roofs are made out of steel sheets, which have been coated with a lead-tin alloy in the past and more recently a zinc-tin alloy or another nontoxic metal. Because of this coating, the base metal is more durable and more resistant to corrosion enabling it to be used as roofing material. Terne is a specific type of metal roofing material that has been coated with a lead-tin alloy. The term ‘terne’ is Spanish and is derived from the french term. ‘terne’ is a reference description, meaning ‘dull’ or ‘tarnished’ whereby the surface of metal coated with terne is compared with that of uncoated metal.

Tin (Terne) roofing advantages:

- Corrosion resistance: The terne coating and the zinc-tin alloy used in terne roofs protects the underlying metal, preventing rust and corrosion. In this way, terne roofs last longer.

- Durability: Tinned (terne) was considered a resistant material to the Roof, load bearing wind, hail, and heavy snow. The proper maintenance and care of terne roofs also extend to decades.

- Aesthetic options: Standing seam and shingle are the several styles of terne roofing and corrugated panels, etc. It can finish with either a matte or highly polished surface as per the requisite appearance. In some case, terne roofing also painted or finished to provide some color.

- Thermal Expansion: Tin (terne) roofing has a small coefficient of thermal expansion which implies that it tends to have a low degree of expansion or contraction when temperatures fluctuate. This characteristic helps the roofing structure in that there are minimal chances of the roof buckling, warping, or deforming in other ways with time. Thus, terne roofing has the prospect of being more stable and durable in places that have extreme seasonal temperature variations.

- Historic appeal: Terne roofing has tin plated iron sheets which is a combination that has been in use for centuries in different parts & is considered one of the historic building materials. For customers who want to maintain historic ideas when it comes to roofing their buildings, this can be a great idea.

- Environmental considerations: Customers should be aware that traditional terne roofing is no longer in use today as it makes use of a lead-tin alloy which poses health risks to the environment. On the other hand, today’s terne coatings are zinc-tin alloys and are non-toxic, creating corrosion guarantees and never worry about lead exposure in the first place.

- Cost: Tin (terne) has a disadvantage of being more expensive than some other options like galvanized steel. This is due to the cost of terne coating which adds to the overall cost. On the contrary, it is important to note that there are low maintenance costs with a longer lifespan in mind.

- Low maintenance: When compared to other roofing options, terne roofing does not require high degrees of maintenance. The roof, in the event of damage, can be restored by undertaking standard roof inspections and some cleaning if needed.

Zinc

Zinc metal roofs have gained recognition as a premium roofing alternative owing to their strength, appeal, and above all, their unique features. They find use in both residential as well as commercial sectors because of their myriad of exceptional features which include self-healing.

Zinc roofing advantages:

- Self-healing: Zinc roofing is known for its self-healing properties, as it naturally forms a protective layer called zinc hydroxyl carbonate that naturally forms when zinc is exposed to moisture and carbon dioxide in the atmosphere. This layer of zinc hydroxyl carbonate prevents the oxidation corrosion of zinc base and heals itself in instances when the zinc surface gets scratched, ensuring that the roof is durable and requires little attention.

- Longevity: With care and maintenance, zinc roofs can last for an upwards of 80-100 years or even longer. Since it has a long life span, it can be a cost effective option as it does not require replacement as frequent as roofs made with other materials might.

- Corrosion resistance: Zinc has great corrosion resistance and can be used in practically all environments from coastal areas to humid or polluted ones. Its natural properties of being able to self heal promote and sustain its corrosion resistance for life.

- Aesthetic options: There are several kinds of zinc metal roofing such as standing seam, shingles, tiles, and even panels. A natural and matte grey color when started, zinc roofs tend to develop beautiful patinas as they age, which adds character to the roof. There are also options to coat the zinc under weather or use a weathered zinc so as to create the desired look.

- Environmentally friendly: Reducing construction waste can be accomplished by utilizing zinc because it is a recyclable material. Because of its long life and low maintenance requirements, it can reduce the total carbon footprint caused by constructing the roof.

- Lightweight: Since zinc is a rather light material, it allows for less stress on the supporting structures of a building. The low weight increases convenience of transportation and installation thereby decreasing the potential labor costs as well as the time needed to complete the installation.

- Low maintenance: Other materials have a greater requirement of maintenance as compared to Zinc roofing. Inspecting and cleaning the roof regularly is usually enough to prevent damage to the structure even if it is not done frequently.

- Thermal performance: Zinc roofing has good thermal performance. It has the potential of regulating indoor temperatures by reflecting solar radiation which would contribute to a more comfortable interior and mitigate energy usage for cooling systems.

Copper

As contrast to conventional roofing systems, copper roofing is among the few and unique roofing systems with unparalleled qualities that endow them with durability, attractive appearance and reliable service. They have been used historically across different designs and now are suitable for use in residential or commercial purposes because of their characteristic advantages. Another interesting thing about copper roofing is the patina. As your roof ages it will literally change colors from that signature copper color to a weathered green color.

Copper roofing advantages:

- Longevity: Rarely do you get to see a copper roof replaced before a hundred years. Their longevity is tempting, their warranty is impeccable and their maintenance over the years is next to nothing as per practical experiences.

- Patina: One of the most distinctive features of copper roofing is the development of a greenish-blue patina over time due to the natural oxidation process. This patina not only adds an attractive and unique appearance to the roof but also acts as a protective layer, enhancing the roof’s resistance to corrosion and weathering.

- Corrosion resistance: Copper exhibits very high resistance against corrosion and it can be used in applications located in coastal areas or those that have high humidity or pollution. This quality is further improved since it develops patina over time which helps in the long-term maintenance of copper.

- Aesthetic options: Copper roof sheeting is manufactured in different forms including, standing seam, shingles, tiles, and panels. Its value is further enhanced by its natural color and the fact that over time it develops a patina which gives the copper a distinctive touch to any building increasing its appeal to many designs.

- Lightweight: Copper as a roofing material is lightweight. It is advantageous to a building because it minimizes the load to the supporting structures of the building. Its low weight also makes transportation and installation simpler which lowers labor and installation time and cost.

- Low maintenance: Copper roofing is more efficient in terms of maintenance when compared to other roofing materials. A simple routine of regular inspection with occasional cleaning will be enough to maintain the integrity of the roofing material.

- Environmentally friendly: There is an advantage in using copper in that it is a recyclable material and can help reduce debris generated in the course of construction. Also, due to its lifespan and low maintenance requirements, the use of the roofing material will minimize the overall impact on the environment.

- Thermal performance: The thermal properties of copper roofing are also quite good as it reflects the sun’s rays and thus can help maintain the desired temperatures in a structure above which might make power ups for cooling systems unnecessary.

Metal Roofing Styles

Standing Seam

What is a standing seam metal roof? Standing seam refers to a metal roofing system that features a series of continuous vertical seams that run from the roof’s ridge to the eaves. These seams are formed by interlocking adjacent metal panels, which are typically made from materials like aluminum, steel, zinc, or copper. Instead, these seams can be made by locking adjacent panels made of aluminum, steel, zinc or copper and are placed side by side. The advantages offered by standing seam roofing design over corrugated and metal shingles or other types metal roofs are many.

Standing seam roofing advantages:

- Design and appearance: Clean vertical lines with a modern touch are the hallmark of standing seam metal roofs. This contributes to the creation of architectural beauty in a wide range of construction, both residential and commercial. As opposed to this, other metal roof types like the corrugated type or the metal shingles have a patterned surface and different visuals and thus may be suited for specific designs or architecture.

- Seams and installation: The seams in a standing seam roof are located above the plane of the roof and hence the chances of water seepage and leakages are much reduced. The interlocking design of the panels provides a tighter and more water-resistant joint than the overlapping or exposed-fastener joints commonly used in corrugated metal or metal shingles. Such enables better resistance to weathering and increased durability.

- Thermal expansion and contraction: The components of standing seam metal roofing are specifically engineered to manage the expansion and contraction of metal ever present in extreme temperature changes. This allows for panels to “float” on the roof structure while decreasing the possibility of buckling, or deformation of any type due to stress. This feature might enhance the overall service life, and performance of the roof.

- Ease of maintenance: In comparison to corrugated metal, or metal shingles, standing seam metal roofs are easier to maintain and clean since such roofs have fewer places to contain debris, snow or ice build-up. Clogged raised seams are less likely to result in leaks, while raised seams act as a better barrier against water penetration.

Exposed Fastener

The construction of exposed fastener metal roofs is less costly and complicated to build than concealed fastener systems, such as standing seam metal roofs. They, however have some negatives when examining them relatively to concealed fastener systems.

Exposed fastener roofing advantages and some disadvantages:

- Cost and installation: Exposed fastener metal roofs are less costly and fast to install as compared to concealed fastener systems. This is because the installation is more simplistic as the fastened panels are installed directly to the roof’s structure.

- Aesthetics: The presence of exposed fasteners on metal roofs makes them look more industrial or utilitarian in terms of aesthetics. This style can be appropriate for agricultural, commercial or industrial usage but is not likely to be the best option for homes for example unless the intended look calls for it.

- Maintenance and potential for leaks: One of the major disadvantages of any exposed fastener metal roof is the possibility of leaks due to the penetrated fasteners over time. Screws which penetrate the metal panels become the weak points of the roof system where water can easily seep through. Again, time takes its toll on the fasteners, as they can corrode or loosen up even more resulting in leaks. These types of metal roofs require regular inspection and maintenance in order to elongate their life span.

- Thermal expansion and contraction: There are potential concerns with exposed fastener systems in regard to thermal expansion and contraction of the metal roof that conceals fastener systems are not as affected. As the temperature changes and the metal panels expand and shrink, there is a possibility of the fasteners being stressed and in turn resulting in leaks or other forms of damage . However, there are ways to minimize these issues, such as proper installation practices and the use of appropriate fasteners.

Metal Roofing FAQ

How to Install a Metal Roof:

First and foremost, you should leave metal roof installation to the professionals as it requires specialized knowledge, experience, and specific equipment to achieve a quality result. Metal roof replacement is no joke and there’s a reason it costs more than the standard asphalt roof. There’s an extremely high chance of injury if a homeowner takes on the task themselves in spite of having little to no experience. If you are insistent, here’s a quick and oversimplified overview of the steps it would take.

- Acquire all Require Permits: Make sure you can legally replace your own roof. Many states forbid the act, requiring licensed contractors to perform it to ensure proper housing standards, safety, and documentation. If your state allows the DIY for metal roof replacement, make sure you understand all the state requirements.

- Check your Home Warranty: Would replacing your own roof void your home warranty? Many insurance policies have a strict rule about self-repair that could affect the integrity of the home as a whole. If they find out later, it could void other things that should be covered in the home warranty as well.

- Prepare the Roof: Remove the old roof and plan to dispose of it legally. Some materials are recyclable and others require specific permits to dispose of. Do your research!

- Measure and Order Materials: Accurately measure the roof’s dimensions and order the required metal panels, considering the type of metal, gauge, and finish. Take into account mistakes, overhang, and any special features that must be custom built.

- Install Eave Trim and Underlayment: Attach eave trim along the edges and install an underlayment for additional weather protection. Be incredibly careful as metal roofs can tend to have no texture and can be extremely slippery.

- Install Metal Panels: Start at one corner and attach metal panels using appropriate fasteners. Overlap panels according to manufacturer guidelines, ensuring a watertight seal. Overlapping panels incorrectly can lead to extensive damage and an entire new replacement. Do not cut corners to save a few dollars. You’re risking the integrity of your home structure.

Secure Ridge and GableTrim: Install ridge and gable trim to complete the roofing system. Ensure all edges are sealed, and use closure strips for a tight fit. Make sure you’re accounting for attic ventilation and that the gutters and overhand are accurate and to grade.

How Long Does a Metal Roof Last:

Metal roofs are known for their longevity. With proper installation and maintenance, they can last 40-70 years or more! The specific lifespan depends on factors like the type of metal used, local climate conditions, and routine maintenance practices.

How Much Does It Cost to Put a Metal Roof on a 2,000 sq ft House?

The cost of installing a metal roof on a 2,000 sq ft house can vary widely. The cost could range anywhere from $10,000 to $25,000 or more. Factors influencing cost include the type of metal, labor expenses, roof complexity, and geographic location. Instant Roofer can help you estimate this cost accurately with our metal roof cost calculator. Just enter your address and we will do the rest.

How to Clean a Metal Roof?

WARNING: It is highly inadvisable to clean your own metal roof as the best way is using soap and water, which makes a metal roof a trap for slipping and falling! Roof cleaning can easily be handled by professionals as well, don’t risk your life just to clean some mildew. If you are insistent, read more on our blog, “How to clean a metal roof?” but here is a quick summary.

- Purchase Non-Slip Shoes: Safety first! Purchase the highest rated non slip shoes you can find!

- Remove Debris: Clear leaves, branches, and other debris.

- Wash with Mild Detergent: Use a mixture of water and a mild detergent to clean the surface. Avoid abrasive materials that can scratch the finish.

- Rinse Thoroughly: Rinse the roof with water to remove detergent residue.

Prevent Algae and Moss: Apply a zinc or copper sulfate solution to prevent algae and moss growth.

How to Paint a Metal Roof:

Again, metal roofs present a variety of dangerous situations that should best be left to the professionals, but you can normally paint your own roof legally!

- Clean the Surface: Remove dirt and debris. Be extremely careful as this can lead to slipping and falling off the roof very easily!

- Repair and Prime: Repair any rust spots, prime the surface, and allow it to dry. This can include sanding or pressure washing, so please be careful and wear non-slip shoes.

- Choose High-Quality Paint: Select a high-quality metal roof paint designed for your specific type of metal. It’s incredibly important to choose the type of paint for your specific metal or it will begin peeling and wearing down extremely fast!

Apply Paint: Use a brush, roller, or sprayer to apply the paint evenly. Follow manufacturer instructions for the number of coats.

How to Overlap a Metal Roof?

Once again, be extremely careful when working on your own roof and we recommend leaving these situations to licensed roofing contractors every time. If you just need to replace a single panel, we still recommend getting a quote for a quick repair as doing this incorrectly will allow water to seep under your roof.

To overlapping metal roofing tiles:

- Start at the Eave: Begin installing panels at the eave, overlapping each subsequent panel over the previous one.

- Follow Manufacturer Guidelines: Consult the manufacturer’s instructions for the recommended overlap distance, typically around 2 inches.

Use Fasteners Correctly: Secure panels with appropriate fasteners, ensuring they penetrate both layers for a secure fit.

What Is a Standing Seam Metal Roof?

A standing seam metal roof is a type of metal roofing system featuring vertical panels with raised seams. The seams are joined or “locked” together, creating a continuous, watertight surface. This design enhances durability and provides a sleek, modern appearance. Standing seam roofs are popular for their weather resistance, minimal maintenance requirements, and suitability for various architectural styles. Installation involves fastening the raised seams without penetrating the metal, preserving the roof’s integrity.